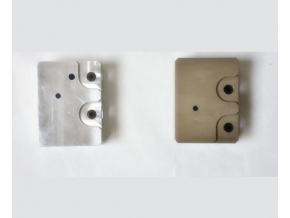

For the product quality of CNC parts, whoever improves the product quality of users will get customers. For the improvement of processing technology, all walks of life have not stopped. Taking the hard oxidation industry as an example, electroplating oxidation was adopted for early products, which was recognized by the market because of its low cost and easy control. However, with the development of product surface treatment technology, First, in order to seize the market, the manufacturer of this product adopts aluminum shell. This material has better hand feel and more beautiful, and can be made into high-quality parts. In the surface treatment method, it adopts advanced hard oxidation treatment, which has texture and good appearance. The important thing is that hard oxidation strengthens the surface quality of the product, increases the corrosion resistance, and makes the quality of the product more stable, Long service life, recognized by the market.

In today's manufacturing production, many product customers need hard oxidation surface treatment in design. How to ensure the quality of hard oxidation products in batch production. When processing the products in the hard oxidation plant, if the surface treatment of CNC precision parts does not reach the required oxidation thickness, it will not meet the customer's order requirements. It is necessary for the hard oxidation plant to have sufficient technical equipment and experienced technicians, so that the customer's products can have higher added value and the overall industry can be developed.

CNC parts processing is an important processing part in the manufacturing industry. Many cutting-edge machines and parts need CNC parts with high precision and hardness. In the processing and production, the surface treatment effect of parts will directly affect the product quality. Therefore, enterprises should pay high attention to the selection of hard oxidation processing plants.

Knurling processing

(1) Install the workpiece. The installation must be as firm as possible.

① When installing the workpiece, the length of the protruding chuck shall be short.

② Long workpieces are supported by centers.

③ When turning the outer circle of knurling, its diameter shall be about 0.25mm smaller than the final dimension.

(2) Install the knurling knife.

① Observe whether the chips on the knurling knife are removed. If necessary, clean it with a wire brush.

② When installing the knurling knife, align its pivot pin and deflect it by a small angle.

④ Clamp the tool firmly.

(3) Workpiece knurling.

① Low cutting speed and large feed are selected.

② Start the machine spindle and apply sufficient coolant to the knurling knife.

③ Shake the knurling knife to cut into the workpiece and apply pressure until a full diamond pattern is formed.

④ After transverse feed, feed longitudinally until the required knurling length is obtained.

⑤ Shake the knurling knife to leave the workpiece quickly.

(4) Chamfering. On the end face of the workpiece, remove the burrs by cutting a depth of 45 ° chamfering to the bottom of the knurled groove. Center height.

③ Visually adjust the knurling knife and deflect it to a small angle for easy introduction.

④ Clamp the tool firmly.

(3) Workpiece knurling.

① Low cutting speed and large feed are selected.

② Start the machine spindle and apply sufficient coolant to the knurling knife.

③ Shake the knurling knife to cut into the workpiece and apply pressure until a full diamond pattern is formed.

④ After transverse feed, feed longitudinally until the required knurling length is obtained.

⑤ Shake the knurling knife to leave the workpiece quickly.

(4) Chamfer. Remove burrs on the end face of the workpiece by cutting a 45 ° chamfer to the bottom of the knurled groove.

scan

scan