Have you ever heard of the tap machining method of CNC machining?

1、Classification and characteristics of tap machining

Using tap to process threaded hole is the most commonly used processing method.It is mainly suitable for threaded holes with small diameter(D<30)and low requirements for hole position accuracy.

In the 1980s,the flexible tapping method was adopted for threaded holes,that is,the flexible tapping chuck was used to clamp the tap,and the tapping chuck can be used for axial compensation to compensate the feed error caused by the non synchronization between the axial feed of the machine tool and the spindle speed,so as to ensure the correct pitch.Flexible tapping chuck has complex structure,high cost,easy damage and low processing efficiency.In recent years,the performance of CNC machining center has been gradually improved,and the rigid tapping function has become the basic configuration of CNC machining center.

Therefore,rigid tapping has become the main method of thread machining.

That is,the tap is clamped with a rigid spring collet,and the feed of the spindle is consistent with the spindle speed controlled by the machine tool.

Compared with the flexible tapping chuck,the spring chuck has the advantages of simple structure,low price and wide application.In addition to clamping the tap,it can also clamp the end milling cutter,drill bit and other tools,which can reduce the tool cost.At the same time,rigid tapping can be used for high-speed cutting,improve the service efficiency of the machining center and reduce the manufacturing cost.

2、Determination of threaded bottom hole before tapping

The processing of threaded bottom hole has a great impact on the service life of tap and the quality of thread processing.Generally,the diameter of the threaded bottom hole drill bit is close to the upper limit of the diameter tolerance of the threaded bottom hole,which can reduce the machining allowance of the tap,reduce the load of the tap and improve the service life of the tap.

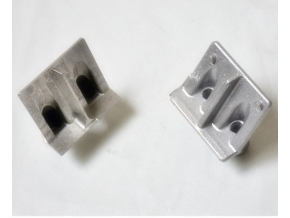

3、Tap selection

When selecting taps,first of all,the corresponding taps must be selected according to the processed materials.The tool company produces different types of taps according to different processing materials,and special attention should be paid to the selection.

Because the tap is very sensitive to the processed material relative to the milling cutter and boring cutter.For example,using a tap for processing cast iron to process aluminum parts is easy to cause thread dropping,disorderly threading and even tap breaking,resulting in workpiece scrapping.Secondly,pay attention to the difference between through-hole tap and blind hole tap.The front guide of through-hole tap is long,and the chip removal is front chip.The front guide of the blind hole is short,and the chip removal is the rear chip.Machining blind holes with through-hole tap can not guarantee the machining depth of threads.In addition,if a flexible tapping collet is used,it should also be noted that the diameter of the tap handle and the width of the square should be the same as that of the tapping collet;The diameter of tap shank for rigid tapping shall be the same as that of spring jacket.In short,only a reasonable selection of taps can ensure the smooth processing.

4、NC programming of tap machining

The programming of tap machining is relatively simple.Now the machining center has generally solidified the tapping subroutine,which only needs to assign values to each parameter.However,it should be noted that the meaning of some parameters is different due to different NC systems and different subroutine formats.

Keyword:CNC machining

Article source:http://www.wxqnkj.com/

scan

scan